Sourcing Arcade Machine Parts: Tips for Manufacturers

- Sourcing Arcade Machine Parts: Practical Tips for Arcade Machine Manufacturer

- Why smart sourcing matters for an arcade machine manufacturer

- Define product and component specifications early

- Identify and qualify suppliers: local vs. overseas considerations for arcade machine manufacturer

- Key arcade components and sourcing tips for manufacturers

- Vendor scorecard: what to measure

- Quality control and testing protocols for arcade machine manufacturers

- Compliance, certifications and safety — what an arcade machine manufacturer must know

- Logistics, lead time management and inventory strategies for arcade machine manufacturers

- Cost optimization without sacrificing quality for arcade machine manufacturers

- When to partner with a full-service arcade machine manufacturer

- Why choose Guangzhou Dinibao as your arcade machine manufacturer and sourcing partner

- Core products and competitive strengths

- Practical checklist for sourcing arcade parts — at-a-glance

- FAQ — Common questions about sourcing for arcade machine manufacturers

- Q: How do I balance cost and quality when selecting a joystick supplier?

- Q: What lead times should I expect for custom PCBs and displays?

- Q: How can I reduce warranty claims for ticket and payout systems?

- Q: Should I consolidate suppliers or diversify?

- Contact and call-to-action

- References

Sourcing Arcade Machine Parts: Practical Tips for Arcade Machine Manufacturer

Why smart sourcing matters for an arcade machine manufacturer

Sourcing is more than buying parts — for an arcade machine manufacturer it determines product reliability, margin, time-to-market, and long-term brand reputation. Poor component choices lead to downtime, higher maintenance costs for operators, and warranty claims. Thoughtful sourcing reduces production bottlenecks, improves customer satisfaction for game center operators, and enables faster rollouts of new titles or cabinet designs.

This guide explains the sourcing lifecycle for arcade parts (from PCB and displays to joysticks and ticket mechanisms), supplier selection best practices, quality assurance, cost-control tactics, logistics and compliance, and how to leverage a manufacturer partner for a one-stop solution.

Define product and component specifications early

As an arcade machine manufacturer, start with a precise bill of materials (BOM) and performance specs for each machine model. Key items to specify:

- Electrical and safety standards (input voltage ranges, surge tolerance, grounding).

- Mechanical life expectations (e.g., joystick switches cycles, button actuation cycles).

- Environmental tolerances (temperature, humidity for installation locations).

- Interchangeability and modularity (standard connectors and mounting points).

- Firmware and software interfaces (communication protocols, MCUs, update methods).

Having clear specifications enables objective supplier evaluation, reduces custom engineering work, and shortens qualification time. Document specs in a Supplier Data Sheet and include acceptance criteria and testing methods.

Identify and qualify suppliers: local vs. overseas considerations for arcade machine manufacturer

Supplier selection balances cost, lead time, quality, and risk. Typical sources: local electronic shops, specialized arcade parts vendors, ODM/OEM manufacturers, and aftermarket suppliers.

Pros and cons (summary):

| Sourcing Option | Advantages | Risks |

|---|---|---|

| Local suppliers | Faster shipping, easier communication, simpler returns | Higher unit costs |

| Overseas OEM/ODM | Lower cost, volume capacity, engineering support | Longer lead times, QC complexity |

| Aftermarket/third-party | Lower lead time for spare parts | Variable quality, IP concerns |

| Direct component manufacturers | Best for electronic components, consistent supply | Requires larger MOQs |

Sources: industry supply-chain best practices and consulting (Deloitte, McKinsey).

Qualification steps:

- Request documentation: ISO 9001, quality manuals, test reports, UL/CE certifications where applicable.

- Samples and stress testing: lifecycle tests, vibration, power cycling, and environmental exposure.

- Factory audits: capacity, worker skill levels, quality processes, traceability.

- Pilot runs: a short production batch to validate assembly and BOM accuracy.

Key arcade components and sourcing tips for manufacturers

Below are the common parts with practical sourcing guidance.

PCBs and electronics: Use reputable contract manufacturers with IPC-A-610 compliant assembly and visible quality metrics. Ask for boM version control, conformal coating options for humid environments, and ESD controls.

Displays (LCD/LED/Touch): Specify brightness, refresh rate, viewing angles, and anti-glare coatings. For interactive touch screens, define touch technology (capacitive vs. resistive) and replacement procedure.

Power supplies: Buy supplies that meet regional safety standards and offer surge protection. Consider medical/industrial-grade PSUs if machines are in high-usage centers.

Controls (joysticks, push buttons): Insist on lifecycle ratings (e.g., 1–5 million cycles). For parts that bear heavy use, choose brand-name microswitches or mechanical encoders.

Ticket and coin mechanisms: Source mechanisms compatible with multiple currencies and ticket types. Ensure firmware supports configurable payout parameters.

Cabinets and mechanical parts: Verify wood/metal quality, finishes, and fastener standards. For outdoor or semi-outdoor machines, use treated wood or powder-coated steel to resist corrosion.

Wiring harnesses and connectors: Use keyed connectors, color-coding, and clear documentation to reduce assembly errors and field maintenance time.

Vendor scorecard: what to measure

Create an objective scorecard that includes: price, lead time, defect rate, on-time delivery, responsiveness, certification, and R&D/support capabilities. This helps balance short-term savings versus long-term reliability.

Quality control and testing protocols for arcade machine manufacturers

Quality control should be systematic and documented. Core QC steps:

- Incoming Inspection (IQC): Check components for specification compliance, visual defects, and perform random functional tests.

- In-Process Control (IPQC): Monitor assembly processes, torque settings, solder quality, and firmware flashing procedures.

- Final Quality Inspection (FQA): Full functional testing of machines, burn-in for 24–72 hours depending on usage profile, and cosmetic inspection.

- Traceability: Assign batch numbers, keep BOM revision history, and capture test logs for each unit.

Automated test fixtures (ATE) and software-based test scripts reduce human error. For ticket and payout systems, simulate heavy usage to validate motor longevity and sensor reliability.

Compliance, certifications and safety — what an arcade machine manufacturer must know

Regulatory requirements vary by market. Common certifications and considerations:

- Electrical safety: CE (EU), UL/CSA (North America), PSE (Japan).

- EMC/EMI testing: Ensure machines don’t interfere with other equipment and comply with regional limits.

- RoHS/REACH: Confirm components meet hazardous substance regulations in relevant markets.

- Local gaming/coin-op regulations: Some jurisdictions require specific approvals for redemption and payout equipment.

Plan certification early. Using pre-certified modules (SMPS, displays) can speed approvals, but you still need system-level testing.

Logistics, lead time management and inventory strategies for arcade machine manufacturers

Long lead times for some components (displays, custom PCBs) are common. Strategies to manage risk:

- Safety stock: Maintain buffer stock for critical parts based on consumption and supplier reliability.

- Multiple-source strategy: Qualify alternate suppliers to avoid single points of failure.

- Vendor-managed inventory (VMI): Let key suppliers hold stock in a near-site warehouse to reduce your carrying costs while shortening lead times.

- Forecasting alignment: Share rolling forecasts with suppliers to enable capacity planning.

When importing parts, factor in customs clearance, tariffs, and local lab-testing times. For fast-moving spare parts, consider local warehousing in major markets.

Cost optimization without sacrificing quality for arcade machine manufacturers

Cost-cutting that harms quality costs more over the product lifecycle. Instead, focus on strategic cost optimization:

- Design for manufacturability (DFM): Simplify assembly steps, reduce unique fasteners, and standardize modules across models.

- Volume-based pricing: Aggregate orders across SKUs to negotiate lower part pricing.

- Value engineering: Re-evaluate expensive components for functionally equivalent alternatives with rigorous testing.

- Total cost of ownership (TCO): Compare suppliers on TCO (warranty claims, replacement frequency), not just unit price.

When to partner with a full-service arcade machine manufacturer

For operators and developers building game centers, partnering with a full-service arcade machine manufacturer can save time and mitigate risk. A strong manufacturing partner provides integrated services: sourcing, engineering, testing, logistics, local compliance support, and after-sales.

Working with a partner that offers one-stop solutions helps scale projects — from pilot arcades to multi-location rollouts — while ensuring consistent machine performance and unified support.

Why choose Guangzhou Dinibao as your arcade machine manufacturer and sourcing partner

Guangzhou Dinibao Animation Technology Co., Ltd. is located in Panyu District, Guangzhou City, and has specialized in manufacturing and exporting game machines for 18 years. Provide one-stop purchasing solutions for arcade centers. We are the only game machine company that offers games with cheap prices and the best quality in the market. Quality is the life, and co-development with customers is our company's policy. We have a professional animation team and thus can provide customers with a complete proposal, such as market research, project analysis, planning, program design, theme design, decoration design, operation, and management, to offer you one-stop purchasing and service.

Our arcade machines have been exported to more than 180 countries. And more than 10,000 game centers are using our machines. We also cooperate with many large local chains and have overseas branch offices in places such as India, Chile, Thailand, Vietnam, Turkey, and the United Kingdom. and find dealers worldwide.

As an arcade machine manufacturer, Dinibao brings several sourcing advantages:

- Deep supply chain partnerships: long-standing relationships with component vendors reduce lead times and cost volatility.

- Integrated R&D and animation team: allows rapid prototyping of new game concepts and optimized BOMs.

- One-stop procurement and project services: from market research to installation and operation guidance.

- Proven export experience: knowledge of international compliance and local market customization.

Core products and competitive strengths

Dinibao's main product lines and strengths include:

- Ticket Game Machines (high throughput mechanisms, configurable payouts)

- Simulator Racing Game Machine (high-precision controls, immersive displays)

- Simulator Shooting Game Machine (accurate tracking, scalable stages)

- Redemption Game Machines & Prize Gift Machines (durable mechanics, modular themes)

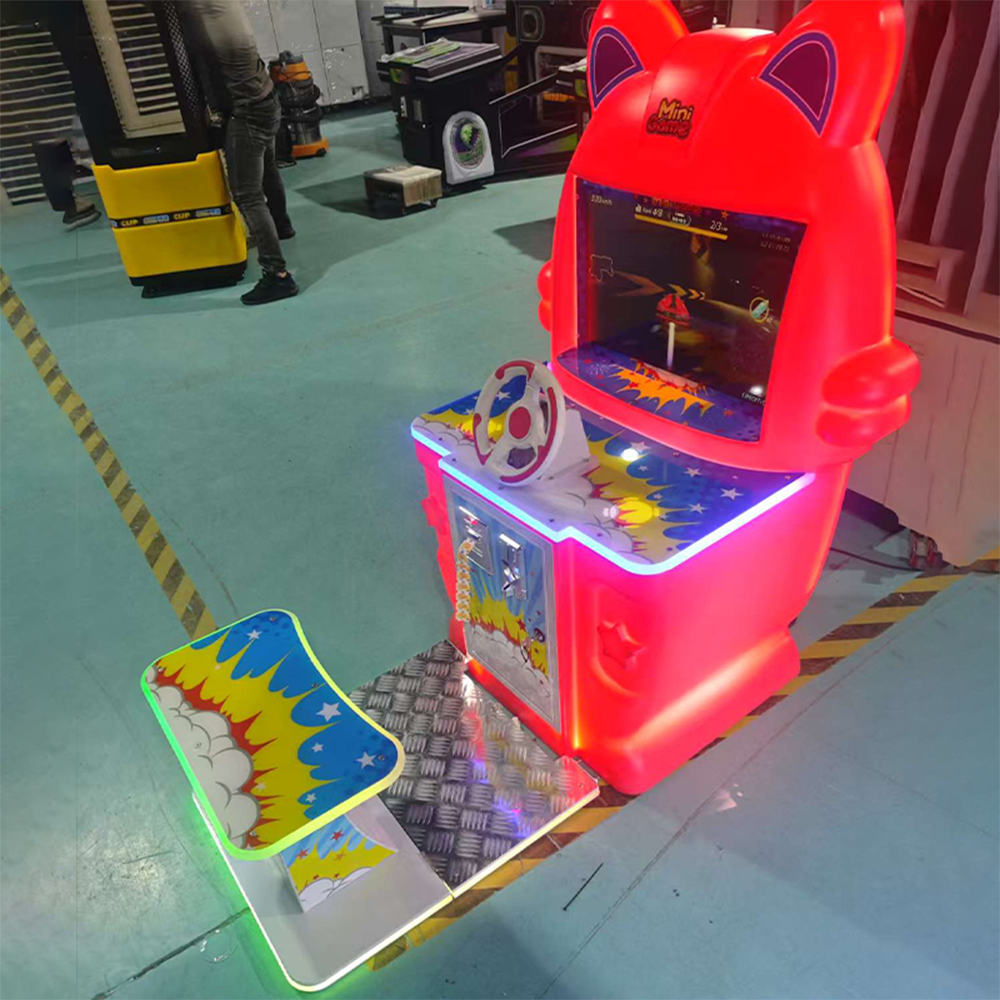

- Kids Arcade Machine & Plastic Swing Machine (safety-certified low-voltage designs)

- Hockey Game Machine, Basketball Game Machine, Fighting Game Machines (commercial-grade cabinets, high-duty-cycle components)

Core competitive advantages: cost-effective manufacturing, robust after-sales support, modular designs for easy maintenance, and localized service through international branches.

Practical checklist for sourcing arcade parts — at-a-glance

- Finalize BOM and specs before RFQs.

- Request certifications and factory audits for key suppliers.

- Require lifecycle and stress-test data for wear items.

- Use pilot runs and ATE for validation.

- Maintain safety stock and multi-source strategy.

- Price on TCO, not just unit cost.

- Plan compliance testing early in the design cycle.

FAQ — Common questions about sourcing for arcade machine manufacturers

Q: How do I balance cost and quality when selecting a joystick supplier?

A: Define required lifecycle cycles and environmental exposure, then source samples from multiple vendors and run accelerated life tests. Consider branded microswitches for high-use controls even if unit cost is higher — the reduced downtime often justifies the investment.

Q: What lead times should I expect for custom PCBs and displays?

A: Custom PCBs typically take 6–12 weeks including tooling, assembly, and testing. Custom displays can take 12–20 weeks depending on panel availability and touch customization. Maintain safety stock and consider alternate suppliers for critical parts.

Q: How can I reduce warranty claims for ticket and payout systems?

A: Use robust motors and sensors, validate under continuous operation for extended periods, and design for easy field replacement. Provide clear maintenance guides and spare part kits for operators.

Q: Should I consolidate suppliers or diversify?

A: Use a hybrid approach: consolidate where supplier performance and volume discounts matter, diversify for high-risk or long-lead items to avoid single points of failure.

Contact and call-to-action

If you are an arcade machine manufacturer or operator looking for reliable sourcing and one-stop procurement solutions, contact Guangzhou Dinibao Animation Technology Co., Ltd. to discuss OEM/ODM options, spare-part programs, and project planning. View products or request a customized proposal to accelerate your project rollout and reduce sourcing risk.

Contact Dinibao sales to get a sourcing consultation and product catalog tailored to your market needs.

References

- Deloitte: Supply Chain Resilience and Diversification (industry white papers and guidance)

- McKinsey & Company: Supplier Selection and Risk Management Best Practices

- ISO 9001: Quality Management Systems (ISO standards overview)

- IPC-A-610 Standard: Acceptability of Electronic Assemblies (assembly quality guidance)

- Company export and distribution claims: Guangzhou Dinibao Animation Technology Co., Ltd. internal records and marketing materials

Top Arcade Air Hockey Table Manufacturers and Suppliers in US

Partnering with Arcade Machine Manufacturers: Contracts

Commercial vs Home Air Hockey Tables: How to Choose

Top 10 Motorcycle Arcade Machine Manufacturers and Supplier Brands in US

Questions you may concerned about

Ticket arcade machine

How are they different from video arcade machines?

Unlike traditional video games, ticket machines combine gameplay with real prize rewards, boosting player excitement.

Prize Machine

Can the machine be customized with our logo or colors?

Yes, we support OEM services for branding, colors, and prize customization.

Hercules

Is Hercules suitable for all ages?

Yes, it is designed to be family-friendly and is suitable for players aged 5 and above.

Piano Keys

Do you provide international shipping?

Yes. As a global arcade game supplier, we deliver and support customers worldwide.

Get in Touch with us

If you are interested in our products and services, please leave us messages here to know more details.

We will reply as soon as possible.

Scan QR Code

Scan QR Code

Youtube

Guangzhou DiniBao Animation Technology Co., Ltd

Guangzhou Dinibao Animation Technology Company Co., Ltd