Eco-Friendly Practices for Arcade Machine Manufacturers

- Eco-Friendly Practices for Arcade Machine Manufacturers

- Why sustainability matters for an arcade machine manufacturer

- Understanding the environmental footprint of an arcade machine manufacturer

- Design for energy efficiency: reduce operating costs for operators and OEMs

- Material choices and recyclability for an arcade machine manufacturer

- Electronics and modularity: extend lifetime as an arcade machine manufacturer

- Supply chain and procurement strategies for an arcade machine manufacturer

- Packaging, transport, and distribution best practices for an arcade machine manufacturer

- End-of-life, take-back and circular strategies for an arcade machine manufacturer

- Certifications, standards and compliance for an arcade machine manufacturer

- Cost-benefit overview for investments by an arcade machine manufacturer

- Implementation roadmap for an arcade machine manufacturer

- Measuring success as an arcade machine manufacturer

- How Guangzhou Dinibao (DINIBAO) integrates eco-friendly practices as an arcade machine manufacturer

- DINIBAO’s one-stop and sustainable strengths for arcade machine manufacturers

- DINIBAO products and core competitiveness for an arcade machine manufacturer

- How DINIBAO can help arcade operators meet sustainability goals

- Practical steps DINIBAO and other arcade machine manufacturers can take now

- Cost, compliance and market benefits for an arcade machine manufacturer

- Decision-makers’ checklist for an arcade machine manufacturer

- Frequently Asked Questions (FAQ)

- Q1: How much energy can I expect to save by buying energy-optimized arcade machines from an arcade machine manufacturer?

- Q2: Are recycled materials reliable for arcade machine construction from an arcade machine manufacturer?

- Q3: Will eco-friendly upgrades increase upfront cost for an arcade machine manufacturer?

- Q4: How can an arcade machine manufacturer handle end-of-life electronics responsibly?

- Q5: What certifications should an arcade machine manufacturer pursue first?

- Q6: How does adopting sustainability practices help attract global customers as an arcade machine manufacturer?

- Contact and next steps — enquire with DINIBAO

- References

Eco-Friendly Practices for Arcade Machine Manufacturers

Why sustainability matters for an arcade machine manufacturer

Arcade machines are durable, high-visibility pieces of equipment that use electricity, plastics, metals, and electronics. For any arcade machine manufacturer, integrating eco-friendly practices reduces operational costs, mitigates regulatory risk, meets customer expectations, and extends product lifetime. Sustainability also strengthens brand trust and opens commercial opportunities with operators who prioritize energy efficiency and responsible sourcing.

Understanding the environmental footprint of an arcade machine manufacturer

Before acting, an arcade machine manufacturer should map the main environmental impacts: material extraction (steel, plastics), electronic components (PCBs, displays), energy consumption during use, packaging and transport, and end-of-life disposal. Quantifying these impacts—through a basic life cycle assessment (LCA) or supplier data—lets you prioritize interventions with the biggest returns.

Design for energy efficiency: reduce operating costs for operators and OEMs

Electricity is often the largest ongoing cost for coin-operated and free-play machines. Design choices that an arcade machine manufacturer can make include using efficient power supplies (SMPS), low-power processors, automatic idle/sleep modes, and LED lighting. LEDs and intelligent power management can reduce a cabinet’s operational energy by 40–80%, depending on previous designs.

Material choices and recyclability for an arcade machine manufacturer

Choosing durable, recyclable materials lowers lifecycle impacts. Opt for powder-coated steel or aluminum for structural elements (both are highly recyclable) and select mono-material plastics where possible to ease recycling. Use recycled-content plastics and certified wood for veneers or decorative panels. Design for disassembly: clearly labeled fasteners and modular subassemblies make repair and recycling straightforward.

Electronics and modularity: extend lifetime as an arcade machine manufacturer

An arcade machine manufacturer that designs modular electronics reduces waste and supports repair. Use standardized connectors, replaceable display modules, and separate the power electronics from game logic. Provide firmware update mechanisms and spare parts lists. Modular design reduces returns and landfill waste because broken components can be replaced without discarding the entire cabinet.

Supply chain and procurement strategies for an arcade machine manufacturer

Sustainability begins upstream. Source components with environmental credentials (recycled metals, RoHS-compliant electronics), work with suppliers who publish environmental policies, and favor local or regional suppliers to reduce transportation emissions. Consolidate orders and optimize container usage to lower freight-related carbon emissions.

Packaging, transport, and distribution best practices for an arcade machine manufacturer

Packaging is a common overlooked source of waste. Design returnable or recyclable packaging, reduce void space, and use cardboard with high recycled content. For distribution, optimize pallet layouts, reduce single-use plastics, and choose carriers with carbon reporting. The right approach reduces damage rates and lowers shipping costs over time.

End-of-life, take-back and circular strategies for an arcade machine manufacturer

Implementing a take-back or trade-in program helps close the loop. An arcade machine manufacturer can refurbish units for secondary markets, harvest reusable parts, and responsibly recycle electronics and plastics. Offering buy-back credits incentivizes operators to return old machines rather than discard them.

Certifications, standards and compliance for an arcade machine manufacturer

Relevant standards and certifications improve market credibility: ISO 14001 (environmental management), RoHS (restriction of hazardous substances), CE marking (for EU safety compliance), and ENERGY STAR (for energy-efficient components where applicable). Achieving and advertising relevant certifications helps win tenders and reassure customers.

Cost-benefit overview for investments by an arcade machine manufacturer

Sustainable upgrades often pay back through energy savings, lower material costs (via recycled content), reduced returns, and stronger sales. Below is a compact comparison of selected interventions and expected benefits (approximate ranges drawn from industry studies):

| Intervention | Typical Benefit | Notes / Source |

|---|---|---|

| LED lighting & efficient power supplies | 40%–80% energy reduction in lighting and standby power | U.S. Department of Energy: LEDs use at least ~75% less energy than incandescent bulbs (approximate) |

| Recycled metal chassis | Up to ~60% energy savings vs virgin steel | World Steel Association / industry averages for recycled steel energy savings |

| Modular electronics & repairability | Extends usable life; reduces waste and spare-part costs | Product-design literature on circular electronics (industry case studies) |

Note: Exact savings depend on machine configuration and usage patterns. Use your own testing and supplier data to model returns.

Implementation roadmap for an arcade machine manufacturer

Suggested phased approach:

- Assess: Conduct a baseline LCA or environmental inventory.

- Quick wins: Switch to LED lighting, introduce sleep modes, and improve packaging.

- Medium-term: Redesign cabinets for modularity, source recycled metals/plastics.

- Long-term: Establish take-back programs, pursue ISO 14001, and work with suppliers for supplier-level improvements.

Measuring success as an arcade machine manufacturer

Track metrics such as energy usage per machine-hour, percentage of recycled content, number of returned/repaired units, and tonnage diverted from landfill. Reporting these metrics to customers and stakeholders demonstrates progress and supports continuous improvement.

How Guangzhou Dinibao (DINIBAO) integrates eco-friendly practices as an arcade machine manufacturer

Guangzhou Dinibao Animation Technology Co., Ltd., located in Panyu District, Guangzhou City, has specialized in manufacturing and exporting game machines for 18 years. As an arcade machine manufacturer with global reach—exporting machines to more than 180 countries and serving over 10,000 game centers—Dinibao is well-positioned to implement and scale sustainable practices.

DINIBAO’s one-stop and sustainable strengths for arcade machine manufacturers

DINIBAO offers one-stop purchasing solutions for arcade centers and emphasizes both competitive pricing and quality: Quality is the life, and co-development with customers is the company's policy. The company’s professional animation team enables complete proposals spanning market research, project analysis, program design, theme and decoration design, and operation and management. These integrated services allow Dinibao to design machines that are optimized for long-term operation, easier maintenance, and lower lifecycle impacts—aligning commercial performance with sustainability goals.

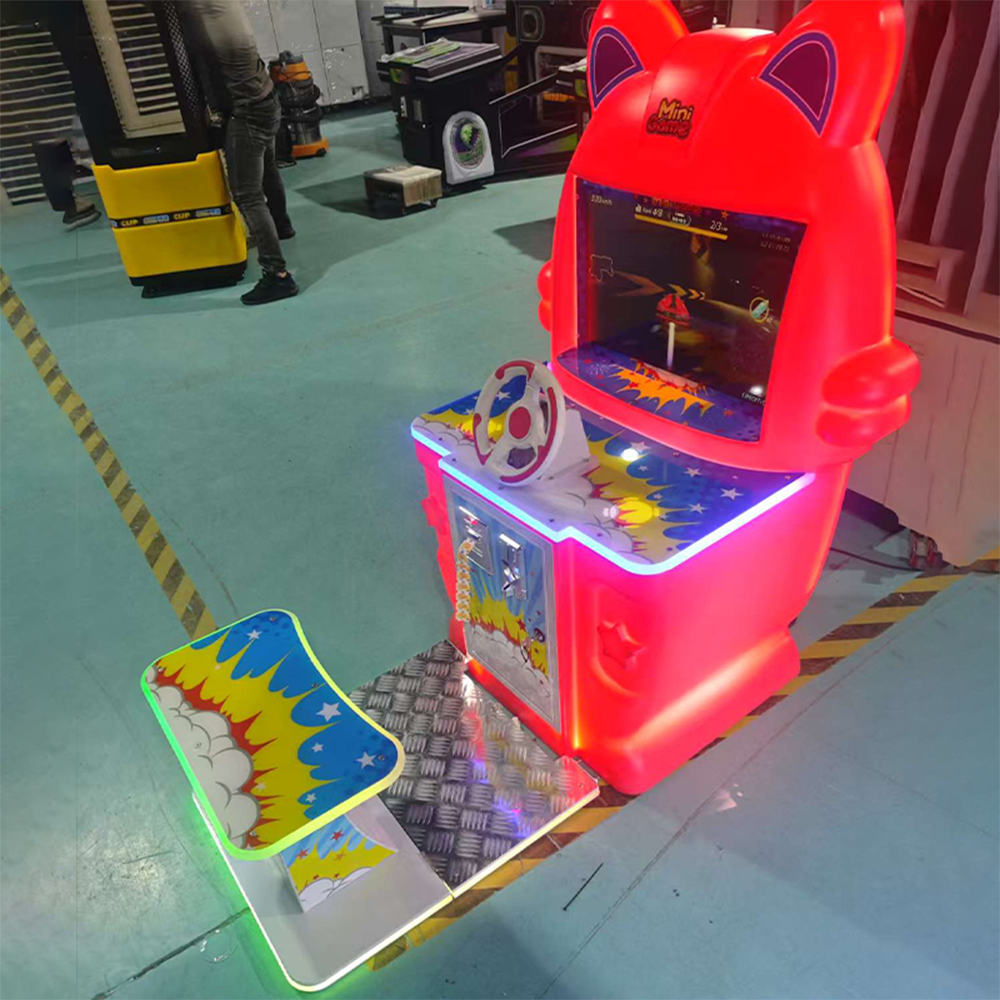

DINIBAO products and core competitiveness for an arcade machine manufacturer

DINIBAO’s main product categories include Ticket Game Machines, Simulator Racing Game Machines, Simulator Shooting Game Machines, Redemption Game Machines, Prize Gift Machines, Kids Arcade Machines, Plastic Swing Machines, Hockey Game Machines, Basketball Game Machines, and Fighting Game Machines. Their core competitive advantages include:

- Extensive manufacturing experience (18 years) and global export capability.

- Integrated design and operation services that enable lifecycle thinking.

- Competitive pricing while maintaining quality standards.

- Strong dealer and service networks, including overseas branches in India, Chile, Thailand, Vietnam, Turkey, and the United Kingdom.

How DINIBAO can help arcade operators meet sustainability goals

Because Dinibao controls design and production, they can implement sustainable choices across product lines: efficient power electronics, modular designs for easier repair and refurbishment, recyclable material selections, and packaging improvements. Their experience with large chain customers also allows them to pilot and scale take-back/refurbishment programs across networks.

Practical steps DINIBAO and other arcade machine manufacturers can take now

For manufacturers like Dinibao, immediate steps include introducing a modular parts catalog, switching to LED illumination, improving supplier environmental requirements, and offering refurbishment packages to returning customers. Over time, pursue third-party certifications and publish annual sustainability metrics to build trust with global buyers.

Cost, compliance and market benefits for an arcade machine manufacturer

Many operators pay for energy and floor space; energy-efficient machines and longer-lasting designs improve ROI and attract sustainability-minded clients and landlords. Compliance with RoHS, CE, and ISO 14001 reduces trade barriers and contractual friction—especially for exports to regulated markets such as the EU. In short, eco-friendly practices are both a compliance necessity and a market differentiator.

Decision-makers’ checklist for an arcade machine manufacturer

When planning sustainability initiatives, decision-makers should check:

- Have we mapped the machine lifecycle and identified highest-impact areas?

- Do our designs support repair and modular upgrades?

- Are suppliers vetted for environmental compliance?

- Can we implement a take-back or refurbishment service?

- What certifications will our target markets expect?

Frequently Asked Questions (FAQ)

Q1: How much energy can I expect to save by buying energy-optimized arcade machines from an arcade machine manufacturer?

Answer: Savings vary, but switching to LED lighting and efficient power electronics typically reduces lighting and standby energy by 40%–80%. Combined with smart power management (sleep modes), total operational energy can drop significantly—often providing payback within 1–3 years depending on usage.

Q2: Are recycled materials reliable for arcade machine construction from an arcade machine manufacturer?

Answer: Yes. Recycled steel and aluminum retain the mechanical properties needed for structural parts. Recycled plastics are suitable for trims and non-structural components if chosen carefully. The key is quality control and supplier certification to ensure consistent material properties.

Q3: Will eco-friendly upgrades increase upfront cost for an arcade machine manufacturer?

Answer: Some upgrades may increase initial costs (e.g., higher-grade recycled materials or certifications), but many measures—LEDs, efficient power supplies, better packaging—can deliver quick paybacks through energy and logistics savings. Modular designs reduce lifecycle costs by lowering repair and replacement expenses.

Q4: How can an arcade machine manufacturer handle end-of-life electronics responsibly?

Answer: Implement a take-back program, partner with certified e-waste recyclers, and design for disassembly so components (batteries, PCBs, displays) can be separated and recycled following local regulations.

Q5: What certifications should an arcade machine manufacturer pursue first?

Answer: Start with compliance standards required for your markets (RoHS, CE) and then pursue ISO 14001 (environmental management) to signal serious commitment. ENERGY STAR or equivalent component-level certifications can help for energy performance claims.

Q6: How does adopting sustainability practices help attract global customers as an arcade machine manufacturer?

Answer: Many international operators and landlords require proof of energy efficiency and environmental management. Sustainable products can lower operating costs for customers and make procurement easier for chains with ESG (environmental, social, governance) targets.

Contact and next steps — enquire with DINIBAO

If you are an arcade operator or investor looking to procure sustainable machines, contact Guangzhou Dinibao Animation Technology Co., Ltd. for solutions tailored to your center. DINIBAO can provide one-stop purchasing, design, market research, and after-sales support. Contact customer service or view our products to discuss energy-efficient configurations, modular replacements, and refurbishment programs that fit your budget and sustainability goals.

References

- Global E-waste Monitor 2020 (United Nations University) — overview of global electronic waste and trends.

- U.S. Department of Energy — guidance on LED lighting energy savings.

- World Steel Association — data on energy savings from recycled steel versus virgin steel.

- ISO standards documentation (ISO 14001 information publicly available) — for environmental management systems.

Top Arcade Air Hockey Manufacturers and Suppliers in Uk

How to Start an Arcade Game Business in Bosnia and Herzegovina: A Complete Step-by-Step Guide

How to Build a DIY Arcade Racing Cabinet: Parts & Steps

How to Vet an Arcade Machine Manufacturer: Checklist

Questions you may concerned about

Star Hero

Is Star Hero profitable for arcade operators?

Absolutely. Its fast-paced gameplay and mix of skill and luck keep players coming back for more.

hammer machine

How does the scoring system work?

The machine uses a digital sensor to measure the impact force of the hit and displays the result instantly on an LED screen.

Monster Smash

What is the warranty period for Monster Smash?

Monster Smash comes with a 12-month warranty, covering both parts and labor.

Sports star

Do you ship internationally?

Yes. We work with a network of arcade game suppliers to provide global delivery and support.

Get in Touch with us

If you are interested in our products and services, please leave us messages here to know more details.

We will reply as soon as possible.

Scan QR Code

Scan QR Code

Youtube

Guangzhou DiniBao Animation Technology Co., Ltd

Guangzhou Dinibao Animation Technology Company Co., Ltd